In 2023, 3D printing is revolutionizing businesses across various sectors. This article dives into the tangible advantages it brings, from cost reduction and rapid prototyping to customization and sustainability.

Whether you’re a startup or an established company, understanding how this can elevate your operations is crucial. Let’s explore these benefits to see how they can make a significant impact.

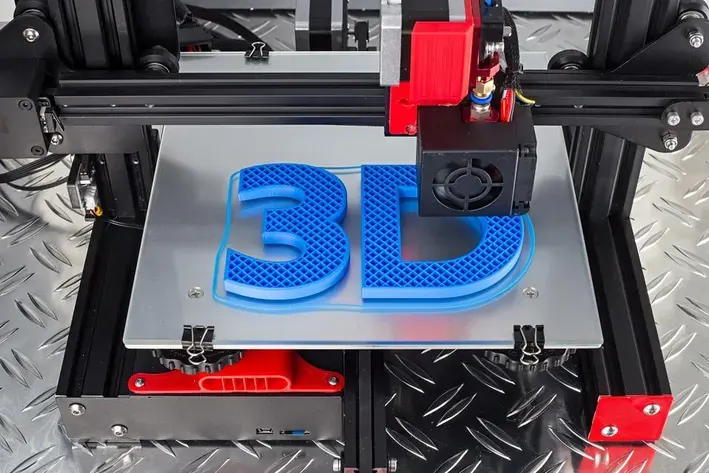

How 3D printing works?

3D printing is the technological revolutionary process of creating three-dimensional objects from a digital file. It works by laying down successive layers of material until the object is complete.

Each layer is a thin slice of the final object. Here’s a simple breakdown:

- Design: First, you need 3D printing designs of the object you want to print. You can create this model using 3D modeling software or by scanning a real object into a 3D file.

- Preparation: Next, the 3D model is prepared for printing using slicing software. This software converts the model into a series of thin layers and produces a G-code file with instructions for the 3D printer.

- Printing: The printer follows the G-code instructions to lay down layers of material. The type of material depends on the printer – it could be plastic, resin, metal, or something else.

- Post-Processing: After printing, the object may require cleaning, curing, or other post-processing to reach its final form.

Throughout the process, the key is precision and control to ensure that each layer is placed correctly, resulting in a high-quality final product.

Cost Efficiency

In the realm of 3D printing services, cost efficiency is a standout benefit.

- Material Savings: Traditional manufacturing methods often involve removing material to create a product, which can result in waste. In contrast, 3D printing adds material layer by layer, using only what’s necessary and reducing waste.

- Reduced Labor Costs: Many 3D printing processes require less manual labor compared to conventional manufacturing. Machines handle the intricate work, potentially lowering labor costs.

- Quick Prototyping: Developing prototypes quickly and at a lower cost allows for rapid testing and iterations, speeding up the time to market.

- Less Need for Storage: Since you can print on demand, there’s less need to store large amounts of inventory, reducing storage costs.

- Transportation Savings: If production is closer to the point of use, you can save on shipping costs.

- Low Entry Costs: With various affordable 3D printers available, even small businesses can adopt the technology without a huge upfront investment.

- Energy Efficiency: Some 3D printing processes use less energy than traditional manufacturing, contributing to cost savings.

Overall, this presents a smart, cost-effective solution for businesses looking to innovate and stay competitive.

Speed in Prototyping

Speed in prototyping is a major advantage in 3D printing, and it’s crucial for businesses aiming to stay ahead.

You can quickly make and test prototypes, making necessary adjustments in real-time. This rapid iteration speeds up the overall design process.

The transition from a digital model to a physical prototype is straightforward and fast, with no need for complex tools or molds. You can immediately check the form, fit, and function.

Customization Capabilities

Custom 3D printing is a standout feature, allowing businesses to tailor products to specific customer needs.

- Personalization: You can easily modify designs to fit individual preferences or requirements, creating products that are truly one-of-a-kind.

- Complexity at No Extra Cost: Unlike traditional manufacturing, complex and intricate designs don’t cost more to produce, giving you freedom to customize without financial constraints.

- Local Adaptation: Products can be adjusted to meet local standards or preferences, even in small batches.

- Medical Applications: In healthcare, 3D printing enables the creation of customized implants and prosthetics, tailored to fit individual patients.

- Fashion and Wearables: Designers are using 3D printing to create customized clothing and accessories, meeting the demand for unique and personalized items.

- Enhanced User Experience: Customized products can lead to better user experiences, as they are designed to meet specific needs or preferences.

- Accessibility: Even small businesses can offer customized products, as 3D printing doesn’t require expensive molds or setups for each new design.

By leveraging the customization capabilities of 3D printing, businesses can offer unique products, differentiate themselves in the market, and meet the growing demand for personalized goods.

Waste Reduction

Waste reduction is a significant advantage for 3D printing companies, playing a crucial role in sustainable manufacturing. Here’s how it makes a difference:

- Additive Process: 3D printing builds objects layer by layer, using material only where it’s needed. This contrasts with subtractive manufacturing, which cuts away material from a larger block, often resulting in significant waste.

- Efficient Material Use: You can achieve high material efficiency, especially in the production of complex or lightweight structures that would be wasteful or impossible to create with traditional methods.

- Recycling Opportunities: Some 3D printing processes allow for the reuse of materials, further reducing waste.

- On-Demand Production: You can print items as needed, reducing the need to produce and store excess inventory that might end up unsold or obsolete.

- Reduced Transportation Waste: If production is closer to the point of use, you reduce the waste associated with transportation and logistics.

- Toolless Manufacturing: Since 3D printing doesn’t require molds or specialized tools for each new design, you avoid the waste associated with creating and discarding these tools.

Supply Chain Simplification

Supply chain simplification through 3D printing means streamlining your operations from start to finish.

With this technology, you can produce parts on demand right where they’re needed, cutting out numerous middlemen and reducing the need for extensive warehousing.

This directly translates to a more responsive and lean supply chain, where you can quickly adapt to changes in demand or disruptions in supply.

You reduce dependence on long-distance transportation and numerous suppliers, which not only simplifies the supply chain but also contributes to sustainability and cost efficiency.

Conclusion

In 2023, 3D printing stands out as a pivotal technology for businesses aiming for innovation, efficiency, and sustainability. It transforms operations with its rapid prototyping, slashing time and costs.

Customization becomes second nature, allowing for personalized products that meet specific needs. Waste reduction is substantial, with a material-efficient, additive process.

Supply chains see a revolution, becoming more resilient and simplified, cutting down on dependencies and logistical hurdles. All in all, it’s a leap towards a more agile, efficient, and innovative future.